WP's HP: HOME | Photo ~ Color ~

[Light] |

?Help? | Deutsch

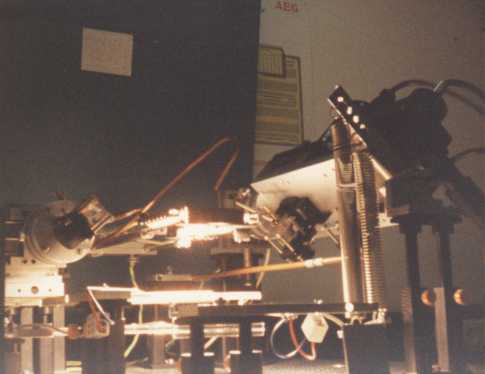

The power of light - almost like in a tanning salon

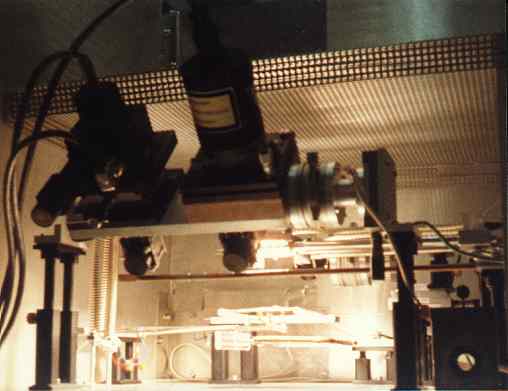

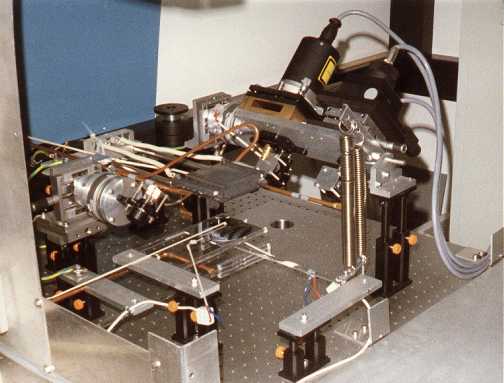

Measurement set-up in working condition

Measuring device, instrumental set-up

Entirely touch-free temperature measurement with an

ellipsometer. Reference dimension is the change of polarization of

a laser beam caused by change in temperature. Twice it runs through

a 1 mm thin quartz pane, which can be heated by halogen lamps.

Its refraction angle of the inner total reflection changes with

temperature. The 180° turn of the beam after the first run through

the glass pane and the entry to the detector after the second run

on the way back are done by prisms.

A calibration curve with polarization change and temperature over

time is the goal.

Existing light bulb - the better stove: Seven 500 W

halogen bulbs easily achieve 1 200 °C

(2 192 °F) within seconds. In industry and semiconductor

processing this setup is often used for RTP (rapid thermal

processing).

The main connection between irradiation and heat is given by

Planck's law. In wave-length form it provides for the temperature

depending spectral irradiation energy density of a black body (the

object with the highest possible emissivity)

r(λ, T) dλ = 2 π h c2/λ5 (exp (h c / (k T) λ-1) -1)-1

with

Planck constant h = 6.6262 10-34 Js

speed of light c = 2.99792 108 m

Boltzmann constant k = 1.3807 10-23 J/K

absolute temperature T in Kelvin

Efficiency of sun and light bulbs in comparison

Displayed in the figure is the irradiation of a black body after

Planck with the temperature of the sun (about 6 100 °C,

11 012 °F), that of a filament of a standard light bulb

(about 2 800±200 °C, 1 472±392 °F) and that of

a halogen bulb (about 3 500±300 °C,

6 332±572 °F).

The visible light region is highlighted in yellow.

Integrated over all wave-lengths one gets with the Stefan-Boltzmann law the temperature depending irradiation density

R(T) = ∫ r(λ, T) dλ = σ T4

with

Stefan-Boltzmann constant σ = 5.670 10-8

W/(m2 K4)

absolute temperature T in Kelvin

When integrating over the visible light wave-length region 380 - 780 nm of the light bulb (temperature of the filament 2 500 K) one calculates a efficiency of about 6%. With the halogen bulb (temperature of the filament 3 200 K) one receives an efficiency of about 16%. Taking in account the low sensitivity of the human eye at the etches of the visible region, here especially the infrared, the »literature values« of 3% for a 100 Watt bulb and maximal 8 to 10% for halogen bulbs, resp., seem to be comprehensive.

Emitting of these light media is not done by a heated

source, but by electron pumping, refer to Franck-Hertz experiment.

In the in principle comparable fluorescent tubes and energy saving

tubes free electrons accelerated by the mains voltage hit electrons

circling around their nucleus and with sufficient energy kicking

them on a higher orbital. After the relaxation time of

10-8 seconds these electrons return to their former

orbital by emitting an ultraviolet photon with energy hf. The

opaque special coating of the glass tube converts these UV

irradiation to visible white light. These lamps show a more or less

continuous spectrum, thus covering »all« wave-lengths.

The semiconductor material of LEDs (light emitting diodes,

luminescence diodes) is directly electrically pumped. The emitted

photons with the energy hf are closely arranged around a frequency

or a wave-length, resp., about ±10 nm to 30 nm, thus they

are monochromatic. For white light one has to bundle a red, a green

and a blue LED, either in separate housings or integrated in one

and the same. (Often there are two blue LEDs due to their low

efficiency.) A discontinuous spectrum is generated by this.

There is a similar possibility compared to fluorescent tubes.

Often a efficient blue LED illuminates a special coating, which

then emits white light with a halfway continuous spectrum.

For conspiracy addicts - yes, industry and state earn much more

with energy saving tubes and LED lamps. And the political pressure

considering that only less than 2% of the energy consumption of a

private household is caused by illumination is rather high. But

there is no doubt that these show a significant higher efficiency

of more than 20% compared to standard light bulbs, even if the

advantages are beautified sometimes.

Just very simple one compares the small torch like light beam of a

LED (maybe just ±6° field angle only), outside it is dark, with the

almost complete 360° illumination of a light bulb. Thus one

calculates as if the LED would illuminate 360° with their full

intensity, too. Additionally one conceals that LEDs as substitute

for household bulbs need a transformer with rectifier, because they

do not work with mains alternating voltage. (LEDs work in

flow direction only at about 2 V to 5 V according to type.) It

almost completely get lost that the installation of high energy

LEDs can turn problematic. While a light bulb gets rid of its power

dissipation by irradiation in infrared in large extend, LEDs just

cool down by convection and heat conduction. A heat sink or an fan

might get necessary.

Concerning energy saving tubes one often disregards the filling

gas (among others mercury), the plastic parts and the hard to rot

printed circuit board with electronics. Fluorescent tubes and

energy saving lamps are hazardous waste, light bulbs can be dropped

into the household waste.

Bottom line: To declare LEDs as general 1:1 substitute for all

light bulbs is as if one carries on stacking bridges with steel

ingots instead of stones after steel was discovered. Energy saving

tubes are more suitable here, or a halogen bulb. As spot or as

large-scale (programmable?) lights LEDs just make more sense.

©WP (1998 -) 2012

http://www.fen-net.de/walter.preiss/e/photo_hf.htm

Update: V8.4, 2012-03-02