WP's HP: HOME

| Photo ~ [Color] ~

Light | ?Help? |

Deutsch

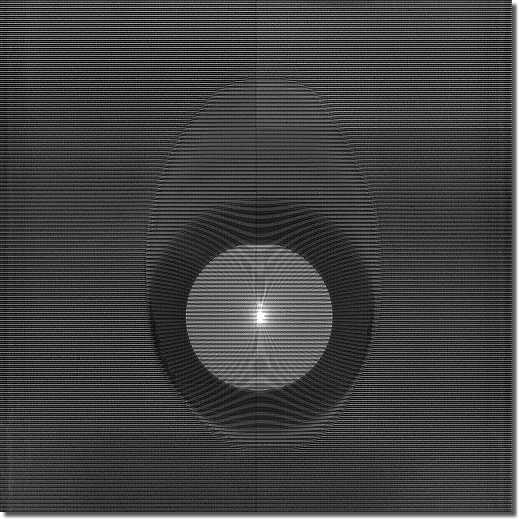

Drop of glue on optical sensor chip - refraction effects

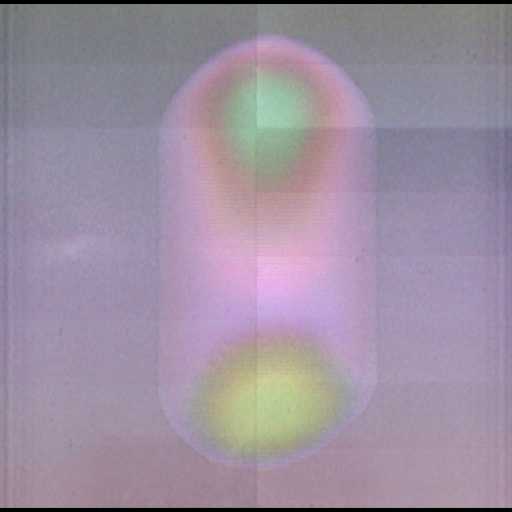

Fault colors due to wrong position interpretation of the not yet

aligned filter

Enjoy the live photo shot during the camera filter assembly, when putting a stripe filter onto an operating(!) CCD sensor.

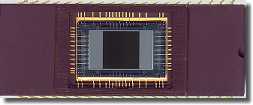

High-speed matrix sensor integrated circuit

Photo made with an opened black-and-white CCD area sensor, which means one with removed glass cover and thus bare silicon. View direction: From the active sensor through a drop of glue on the sensor onto (and through) a Red-Green-Blue line filter on glass substrate into the light source. The algorithm for color recovery is partly inactivated yet.

Black-and-white area sensor EG&G Reticon HS0512JAQ,

resolution 512 pixels x 512 pixels, size 8.19 mm per square.

Exposure: 1/1 000 sec. (The image is post processed with etch

enhancing, because too much light would harden the glue before

adjusting the filter.)

The alignment is done with an accuracy of ±1/4 micrometer, because

the fill factor is close to 100%.

The upper left image was made in the clean room during filtering

the black-and-white sensor. The bright lines are the green ones of

a red - green - blue - green line pattern on the glass substrate.

Each line is 16 microns wide, with an overlap of approx. 1 micron

to each neighbor line.

Viewing at the stack from the side you would see the sensor at the

bottom. Then the glue in an eggcup shape, approx. 0.5 mm high.

And on the top the glass substrate (thickness: 2.0 mm) with

the filter pattern.

What you see in the image (just a suggestion ;-): The egg-shaped

contour shows the original size of the glue drop (on the sensor)

before it has got in contact with the glass substrate. The dark

ring is caused by the flank of the glue eggcup, because the viewing

direction is against the light source. Its circumference is the

contact area between glue and glass substrate. The inner circle is

the optical path through the glue given by the smallest diameter of

the eggcup.

It is necessary for the color recovery that the corresponding

algorithm is familiar which color belongs to each pixel, thus the

color filter is fixed and clearly aligned to the pixel. If this is

not given misinterpretation and thus fail colors happen. In the

image on the lower left the strip filter is not close enough

lowered to the sensor surface. Of course, the not already

completely dispensed glue drop has some influence, too.

Hand optimized color sensor

After finishing: The glue fills the whole space between sensor and glass substrate. The distance between them is then approx. 20 to 30 microns. The glue is hardened by UV exposure and the rest of the sensor (open bond wires!) is sealed by ceramic/epoxy filling.

©WP (1998 -) 2012

http://www.fen-net.de/walter.preiss/e/photo_sc.htm

Update: V8.4, 2012-03-02